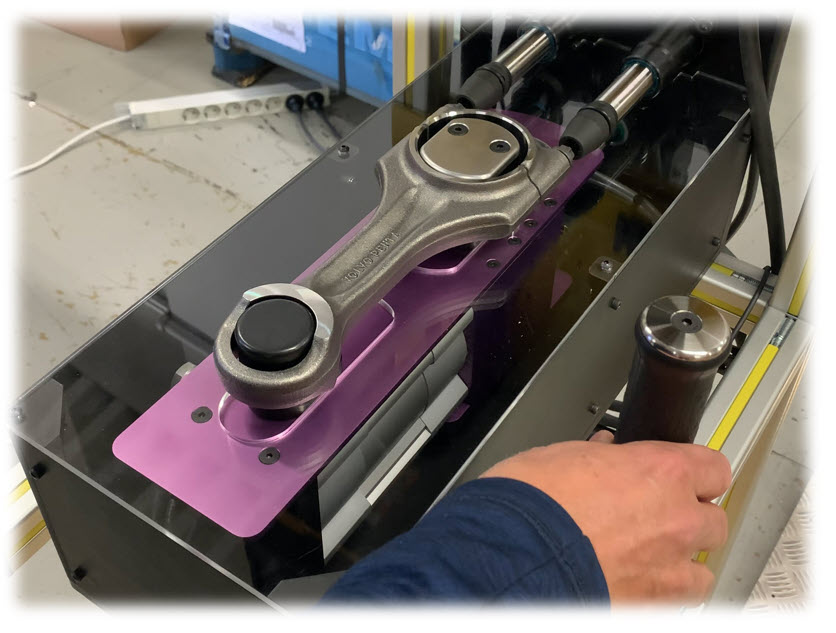

Connection Rod Assembly

Automated connecting rod splitting station

What our Customer Envisioned:

Customer was in need of an equipment that helps the operator to split a connection rod in two halves with as little as possible work from the operator itself.

How We delivered:

We developed an equipment where the unsplitted connecting rod is placed in a fixture by the operator where, after start button is pressed, the station automatically engages two torque tools to the screws, loosens them and later by pneumatic air cylinders pulls the connecting rod in two pieces.

Loosening of screws and assurance that the splitting process is carried out correctly is monitored by the system and operator is informed that all went as intended

Productivity – Our enhancements to the speed and simplicity of the operator’s splitting cycle not only boosted overall operational efficiency and safety but also brought a smile to the operator’s face.

Reliability – A solution crafted to maintain uninterrupted operation, mitigate the potential misuse or mishandling of tools or materials, and minimize the risk of damage or injury, with the added assurance of utilizing high-quality components in the machine.

Design – The design was meticulously crafted to align with the customer’s requirements regarding throughput and the quality of the splitting operation. Our innovative approach, coupled with close communication with the customer, ensured that the delivered solution precisely met their needs and expectations.

Quality – The process stays top-notch thanks to both the reliable surveillance system and the use of high-quality parts. It’s all about ensuring things are done right.

T20208